Spuitgieten, TSG, lakken en assembleren van uw kunststof behuizingen en technische componenten

Nieuws uit onze wereld van kunststof en TSG

Bezoek de ESEF 2024!

01 feb 2024 Wij zullen met een stand aanwezig zijn tijdens dit jaarlijkse evenement voor de maakindustrie. Komt u ons en alle andere interessante exposanten bezoeken? Vraag dan hier een gratis toegangsbewijs aan. lees verder

01 feb 2024 Wij zullen met een stand aanwezig zijn tijdens dit jaarlijkse evenement voor de maakindustrie. Komt u ons en alle andere interessante exposanten bezoeken? Vraag dan hier een gratis toegangsbewijs aan. lees verder'Surveillance visit' bevestigt continuering AS9100

31 okt 2023 Lloyd’s Register Quality Assurance (LRQA) heeft ons medio oktober laten weten dat we onze AS 9100 certificering opnieuw mogen continueren. We hebben deze mijlpaal bereikt en onze processen zelfs verder kunnen optimaliseren. We zijn trots te kunnen melden dat er geen nonconformities zijn geconstateerd tijdens de audit.

31 okt 2023 Lloyd’s Register Quality Assurance (LRQA) heeft ons medio oktober laten weten dat we onze AS 9100 certificering opnieuw mogen continueren. We hebben deze mijlpaal bereikt en onze processen zelfs verder kunnen optimaliseren. We zijn trots te kunnen melden dat er geen nonconformities zijn geconstateerd tijdens de audit.We hebben als spuitgieter voor de luchtvaartindustrie te maken met enorme uitdagingen maar zijn toch in staat aan de hoge verwachtingen in deze branche te voldoen. lees verder

Opnieuw een aanvuling op onze fabriek: een nieuw materialenmagazijn

15 mei 2023 Na de voltooiing van een extra magazijn in 2020, werd begin 2023 begonnen met nieuw magazijn, speciaal bestemd voor materialen en half-fabrikaten.

15 mei 2023 Na de voltooiing van een extra magazijn in 2020, werd begin 2023 begonnen met nieuw magazijn, speciaal bestemd voor materialen en half-fabrikaten.Pekago's groei in de afgelopen jaren maakte externe opslag noodzakelijk. Dit leidde tot onnodig, veelvuldig verplaatsen van goederen en materialen. Vanaf mei 2023 zijn alle materialen, zoals granulaat en masterbatches, centraal opgeslagen in het nieuwe magazijn direct naast onze fabriek. Dit magazijn biedt extra plaats aan 1.250 pallets. lees verder

Elke matrijs als een zonnetje laten lopen is een ambacht

17 jan 2023 Goed onderhoud van spuitgietmatrijzen is essentieel voor een constante kwaliteit van kunststof onderdelen. Tijdens productie worden matrijzen aan grote krachten en hoge temperaturen blootgesteld. Om schade te voorkomen worden ze daarna vertroeteld door onze matrijsmakers.

17 jan 2023 Goed onderhoud van spuitgietmatrijzen is essentieel voor een constante kwaliteit van kunststof onderdelen. Tijdens productie worden matrijzen aan grote krachten en hoge temperaturen blootgesteld. Om schade te voorkomen worden ze daarna vertroeteld door onze matrijsmakers.Onze collega's Maykel Geerts en Pieter Jan Luttikhuis vertellen in een blog enthousiast over wat matrijzen nodig hebben om soepel te blijven lopen. lees verder

Design Guide: lakken van spuitgietdelen

01 okt 2022 "Netjes spuitgieten hoeft niet, de lak maskeert fouten toch wel".

01 okt 2022 "Netjes spuitgieten hoeft niet, de lak maskeert fouten toch wel".Dit is ten dele waar. Maar wanneer al tijdens het ontwerpen en het maken van het kunststof onderdeel rekening wordt gehouden met de nabewerking, vermijd je meestal hoge kosten achteraf. lees verder

Glans ontstaat niet alleen door wrijving: heat/cold-techniek bij spuitgieten

30 apr 2021 Als er zeer hoge eisen worden gesteld aan een mooi (glanzend) oppervlak van kunststof spuitgietproducten is standaard spuitgieten niet meer genoeg. Voor kunststof producten met een kwalitatief hoogstaand glanzend oppervlak investeren wij in de zogenaamde HEAT/COLD-techniek.

30 apr 2021 Als er zeer hoge eisen worden gesteld aan een mooi (glanzend) oppervlak van kunststof spuitgietproducten is standaard spuitgieten niet meer genoeg. Voor kunststof producten met een kwalitatief hoogstaand glanzend oppervlak investeren wij in de zogenaamde HEAT/COLD-techniek.Bij spuitgietproces wordt de hete, vloeibare, kunststof in de relatief koude vormholte van de matrijs gespoten. Een koele matrijs zorgt er mede voor dat de kunststof stolt tot een ‘vast’ product. Hoe te sneller de kunststof stolt, des te sneller kan het product uit de matrijs genomen worden en kan de matrijs opnieuw gevuld worden met nieuwe kunststof. Ook hier geldt: tijd is geld. lees verder

Voortdurend verbeteren

10 apr 2021 Continuous Improvement is hot binnen Pekago. Dat moet ook wel, want we groeien. En om groei mogelijk te maken, is het optimaliseren van processen onontbeerlijk. Sinds twee jaar is Jurgen van Elewout onze continuous improvement engineer.

10 apr 2021 Continuous Improvement is hot binnen Pekago. Dat moet ook wel, want we groeien. En om groei mogelijk te maken, is het optimaliseren van processen onontbeerlijk. Sinds twee jaar is Jurgen van Elewout onze continuous improvement engineer. In die rol begeleid hij de meest uiteenlopende verbeteringsprocessen. “Die afwisseling was juist wat ik zocht”, vertelt Jurgen. Hij werkte al sinds 2005 als engineer bij Pekago toen hij aan zijn huidige functie begon. Aan kennis over onze processen ontbreekt het hem dus niet!

In deze blog vertelt Jurgen aan welke projecten hij zoal werkt. lees verder

Ondernemen in tijden van Corona

08 feb 2021 Ondernemen in tijden van Corona brengt uitdagingen en mogelijkheden met zich mee. Zal de markt krimpen, herstellen of groeien?

08 feb 2021 Ondernemen in tijden van Corona brengt uitdagingen en mogelijkheden met zich mee. Zal de markt krimpen, herstellen of groeien?Deze vraag werd gesteld aan een aantal ondernemers uit de Brabantse maakindustrie, waaronder onze managing director Marcel Verbeek. Hun antwoorden leest u in dit artikel uit Regio Business Magazine. lees verder

Flexibele monitorarm voor ergonomisch mobiel werkstation

29 jun 2020 Voor het Alphatron Medical Innovations bouwt Pekago al jarenlang zogenaamde medicatieboxen (boxen met lades) voor de AMiS. We produceren de spuitgietdelen die we vervolgens nabewerken, lakken, bewerken en assembleren inclusief het installeren van de elektronica.

29 jun 2020 Voor het Alphatron Medical Innovations bouwt Pekago al jarenlang zogenaamde medicatieboxen (boxen met lades) voor de AMiS. We produceren de spuitgietdelen die we vervolgens nabewerken, lakken, bewerken en assembleren inclusief het installeren van de elektronica. Sinds kort maken we ook de behuizingsdelen van de monitorarm voor de AMiS. Deze monitorarm verbetert het ergonomisch gebruikt van het zorgstation en zorgt daarmee voor meer werkcomfort. lees verder

Slagvaste behuizing voor parkeerautomaten

20 jun 2020 Het Duitse Designa Verkehrsleittechnik GmbH levert volautomatische parkeermanagement-systemen aan steden, ziekenhuizen en (internationale) vliegvelden. Voor hun nieuwste modulaire in- en uitrit-terminal “PM Abacus” heeft Pekago de (slagvaste) behuizing gemaakt door middel van thermoplastisch schuimgieten. lees verder

20 jun 2020 Het Duitse Designa Verkehrsleittechnik GmbH levert volautomatische parkeermanagement-systemen aan steden, ziekenhuizen en (internationale) vliegvelden. Voor hun nieuwste modulaire in- en uitrit-terminal “PM Abacus” heeft Pekago de (slagvaste) behuizing gemaakt door middel van thermoplastisch schuimgieten. lees verderOok voor de zorg geldt: 3D-geprint is er eerder, maar spuitgieten gaat sneller!

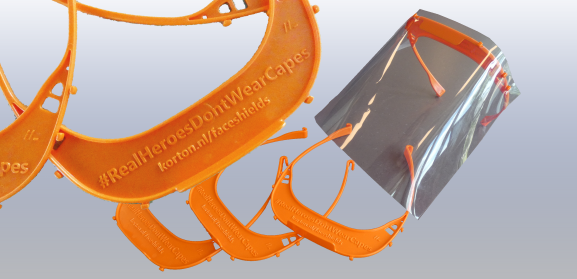

30 mei 2020 In de afgelopen maanden bleken gezichtsmaskers voor o.a. zorgpersoneel een oplossing om dichtbij de patiënt of bewoner te komen, goede zorg te verlenen en de kans op besmetting tot een minimum te beperken. Door de schaarste grepen veel zorginstellingen mis: geen gezichtsmasker te vinden!

30 mei 2020 In de afgelopen maanden bleken gezichtsmaskers voor o.a. zorgpersoneel een oplossing om dichtbij de patiënt of bewoner te komen, goede zorg te verlenen en de kans op besmetting tot een minimum te beperken. Door de schaarste grepen veel zorginstellingen mis: geen gezichtsmasker te vinden! Korton Group is een leverancier van IT-oplossingen aan zorginstellingen. Zij lieten het er niet bij zitten en besloten samen met enkele partners om maskers met een 3D geprinte houder te laten maken. Binnen no time werd er opgeschaald naar 600 stuks per week, waarmee de eerste nood werd gelenigd. De behoefte bleek echter veel groter. lees verder

"Kunststof is essentieel voor het behalen van CO2-doelstellingen in de aerospace"

05 mrt 2020 “Ik durf wel te zeggen dat kunststof een steeds grotere toekomst heeft in de lucht- en ruimtevaart. Kunststof heeft belangrijke eigenschappen waar traditionele vliegtuigmaterialen zoals aluminium niet tegenop kunnen". Aan het woord is Hermann Thorsen, onze key-account manager Aircraft Interiors. In deze blog vertelt hij over de toepassingen van kunststof in de luchtvaart. lees verder

05 mrt 2020 “Ik durf wel te zeggen dat kunststof een steeds grotere toekomst heeft in de lucht- en ruimtevaart. Kunststof heeft belangrijke eigenschappen waar traditionele vliegtuigmaterialen zoals aluminium niet tegenop kunnen". Aan het woord is Hermann Thorsen, onze key-account manager Aircraft Interiors. In deze blog vertelt hij over de toepassingen van kunststof in de luchtvaart. lees verderInserts in kunststof - meer dan een gat voor een schroefje

05 mrt 2020 “Inserts kunnen een kunststof product letterlijk maken of breken”, lacht Jan Rijpert, al 28 jaar Pekago's expert in assemblage van kunststof onderdelen. Afhankelijk van de functie en de eisen aan ... lees verder

05 mrt 2020 “Inserts kunnen een kunststof product letterlijk maken of breken”, lacht Jan Rijpert, al 28 jaar Pekago's expert in assemblage van kunststof onderdelen. Afhankelijk van de functie en de eisen aan ... lees verderUitbreiding Pekago: ons nieuwe magazijn is klaar

05 feb 2020 Pekago groeit sterk en daarom was er grote behoefte aan meer ruimte. De afgelopen maanden is er naast onze fabriek een nieuw magazijn gebouwd met genoeg ruimte om 2.500 pallets op te slaan.

05 feb 2020 Pekago groeit sterk en daarom was er grote behoefte aan meer ruimte. De afgelopen maanden is er naast onze fabriek een nieuw magazijn gebouwd met genoeg ruimte om 2.500 pallets op te slaan.Bekijk in 30 seconden hoe het magazijn 'gegroeid' is! lees verder

Kunststof een oplossing voor zeer agressieve omstandigheden

27 jun 2019 Waar metaal niet voldoet in corrosieve omstandigheden is kunststof vaak een uitstekende oplossing. CirTec ontwikkelde de Crescendo verdamper, een systeem met kunststof 'filterpanelen' om bijvoorbeeld verontreinigd afvalwater te scheiden van verontreiniging door slib, pekel of zware metalen.

Het kunststof voor de filterpanelen moest voldoen aan zware eisen op het gebied van chemische resistentie, hittebestendigheid, sterkte en stijfheid. Hoe we dit hebben opgelost, leest u in deze business case. lees verder

Het kunststof voor de filterpanelen moest voldoen aan zware eisen op het gebied van chemische resistentie, hittebestendigheid, sterkte en stijfheid. Hoe we dit hebben opgelost, leest u in deze business case. lees verder

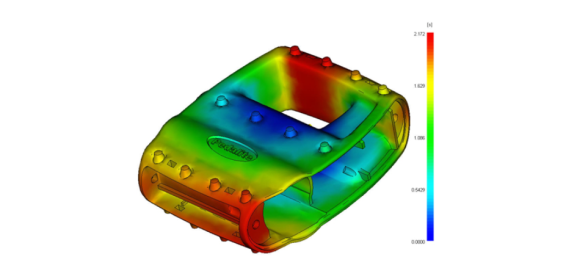

Moldflow-analyse voorspelt veel bij het spuitgieten van kunststof producten

25 jun 2019 Tijdens een moldflow-analyse wordt digitaal gesimuleerd hoe een matrijs zal functioneren en hoe dit kan worden geoptimaliseerd door de verschillende variabelen aan te passen. En dat nog voordat de matrijs daadwerkelijk gemaakt is! Zo kan het spuitgietproces nog voordat het begonnen is nauwkeurig worden bijgestuurd. lees verder

25 jun 2019 Tijdens een moldflow-analyse wordt digitaal gesimuleerd hoe een matrijs zal functioneren en hoe dit kan worden geoptimaliseerd door de verschillende variabelen aan te passen. En dat nog voordat de matrijs daadwerkelijk gemaakt is! Zo kan het spuitgietproces nog voordat het begonnen is nauwkeurig worden bijgestuurd. lees verder"In 20 weken stage leer je veel bij Pekago"

20 jun 2019 Sinds februari heeft Sam Verzeijl stage gelopen op onze afdeling Matrijsbeheer. Nu rond hij zijn stage én zijn opleiding af. lees verder

Ooit gehoord van een 'cobot'?

10 jun 2019 Het verschilt maar één letter van het woord robot, de cobot. De collaborative robot is een apparaat dat sterk doet denken aan de industriële robot, maar vooral is bedoeld om samen te werken met de mens. lees verder

Finishing van kunststof behuizingen zet de puntjes op de “i”

22 mrt 2019 Onze afdeling Finishing draagt zorg voor de afwerking van spuitgietproducten, het voorbereiden van producten die gelakt moeten worden, voor montage en voor het verlijmen van onderdelen. Wilbert Diepstraten, al bijna 25 jaar bij ons in dienst, vertelt over zijn ambacht. lees verder

Herinrichting productieafdelingen

01 feb 2019 Vanzelfsprekend werken wij voortdurend aan optimalisatie van ons bedrijf. Om materiaal- en productiestromen nog overzichtelijker te laten verlopen, heeft onlangs een herinrichting plaatsgevonden waarbij onder andere de verschillende afdelingen meer dan voorheen van elkaar gescheiden zijn door wanden. lees verder

Groene stroom bij Pekago

15 jan 2019 Ook wij proberen ons steentje bij te dragen aan een schoner milieu en daarom draait Pekago op groene stroom. lees verder

Beoordeling van maakbaarheid is altijd onze eerste stap

22 nov 2018 “Wij als engineers bij Pekago delen onze kennis en kunde graag met onze opdrachtgevers. Als we al in een vroeg stadium bij de ontwikkeling van een product betrokken worden, geeft dat het beste ... lees verder

Matrijzen uit China zijn niet alleen goedkoper

04 okt 2018 “Matrijzen uit China zijn natuurlijk goedkoper, maar dat is niet de belangrijkste reden dat we ze daar kopen. Het klinkt misschien vreemd, maar ik heb aan de andere kant van de wereld dingen ... lees verder

Beoordeling van maakbaarheid is altijd de eerste stap

28 dec 2017 “Wij als engineers bij Pekago delen onze kennis en kunde graag met onze opdrachtgevers. Als we al in een vroeg stadium bij de ontwikkeling van een product betrokken worden, geeft dat het beste resultaat. Maakbaarheid is daarbij een van de eerste dingen die we beoordelen”. lees verder

AS9100 in de praktijk: altijd blijven opletten

21 mrt 2017 "We zien de eisen die de AS9100-norm ons stelt niet als verplicht nummertje, de keuze voor die norm biedt een keuze voor een richting. In de food denken medewerkers ook al niet meer na over het ... lees verder

Kunststof lakken: waarom en hoe?

07 feb 2017 "Door kunststof te lakken kun je het een mooi uiterlijk geven, dat vinden onze klanten steeds belangrijker. Zoals medische klanten die een gladde band metallic op hun apparaat willen zien, ... lees verder

Grote kunststof delen AeroCat vliegtuigtrolley bij Pekago in productie

31 mrt 2015 Recentelijk heeft AeroCat, dat in 2011 een kunststof vliegtuigtrolley op de markt introduceerde, besloten om de productie van de grote spuitgietdelen voor de trolley te transfereren van een spuitgieter in de VS naar Pekago. De onderdelen zullen bij Pekago op de 1500T machine worden gespuitgiet en vervolgens nabewerkt. Op slechts 15 km afstand worden de verschillende onderdelen door AeroCat geassembleerd tot een complete trolley. lees verder

Geen gereedschapskist meer voor prikdiensten

31 mrt 2015 In samenwerking met Aptus Cases en Promea Industrial Design wordt hard gewerkt aan de ontwikkeling van een UN-goedgekeurde koffer. lees verder

Pekago op de Aircraft Interiors Expo 2015

31 mrt 2015 Van 14 tot en met 16 april vindt Aircraft Interiors Expo 2015 in Hamburg plaats. Aircraft Interiors Expo is ’s werelds grootste beurs voor vliegtuiginterieurs. Voor Pekago hét evenement bij uitstek om haar kennis en kunde op het gebied van de verwerking van high performance plastics voor cabin, galley en lavatory equipment te etaleren. lees verder

Additieven in kunststof - verbetering van producteigenschappen

30 mrt 2015 Door additieven aan kunststof granulaat toe te voegen kunnen eigenschappen worden verkregen die anders niet mogelijk zijn. lees verder

Vijfde en laatste A350-testvliegtuig vliegt voor het eerst

15 aug 2014 De vijfde en laatste Airbus A350 XWB uit de eerste serie testtoestellen heeft eind juni een geslaagde testvlucht gemaakt. MSN005 is het tweede testtoestel dat uitgerust is met een ... lees verder

Product uitgelicht: De “food bin” van Lely Industries N.V.

23 jul 2014 Automatisering in de agrarische sector neemt een steeds hogere vlucht; zo ook voor het melken van de koe. Lely Industries is marktleider op het gebied van melkrobots, waarvan er ruim 19000 over de hele wereld in bedrijf zijn. lees verder

Terugblik ESEF 2014

23 jul 2014 Pekago kan terugkijken op een geslaagde deelname aan de beurs ‘ESEF 2014’, de grootste vakbeurs in de Benelux op het gebied van toeleveren, uitbesteden, productontwikkeling en engineering. lees verder

Vulstoffen ter verbetering producteigenschappen

23 jul 2014 Dat kunststof in allerlei soorten verkrijgbaar is zal u niet vreemd zijn. Voor elke specifieke toepassing is er keuze genoeg. Gelukkig maar, want aan bijvoorbeeld tandwielen worden heel andere eisen gesteld dan aan behuizingen of verpakkingen. lees verder

AS 9100 certificering Pekago is een feit

20 mrt 2014 Als één van de weinige kunststofverwerkende bedrijven in Nederland heeft Pekago het kwaliteitscertificaat AS 9100 behaald. Deze norm kwalificeert organisaties die toeleveren aan de vliegtuigbouw. ... lees verder

Pekago in de luchtvaart

08 nov 2013 De hevige concurrentiestrijd in de luchtvaart spitst zich met name toe op reductie van de gebruikskosten. Die kosten worden vooral bepaald door het gewicht van het vliegtuig: hoe meer gewicht, hoe hoger het brandstofgebruik. lees verder

Matrijzen succesvol verhuizen

08 nov 2013 Een goed voorbeeld van het verplaatsen van matrijzen: rugschalen welke gebruikt worden in stoelen van NS-treinstellen. lees verder

Pekago met ISO 13485 goed uitgerust voor medische apparatuur

09 okt 2013 Om medische hulpmiddelen op de Europese markt te mogen brengen, stellen de Europese medische richtlijnen hoge eisen aan het door de fabrikant te voeren kwaliteitsmanagementsysteem. Een geaccepteerde manier om aan deze eisen te voldoen is het invoeren van een kwaliteitsmanagementsysteem volgens EN ISO 13485:2003. Dit is de medische variant van ISO 9001. Deze norm bevat andere en meer vereisten dan de ISO 9001. lees verder

Ontwikkeling Medicatiebox Alphatron Medical Innovations

05 jun 2013 Pekago heeft voor de medicatiebox van Alphatron Medical Innovations de kunststof delen geproduceerd en de complete assemblage verzorgd.

Hoe het volledige proces van ontwikkeling tot en met realisatie is verlopen kunt u lezen in deze business case. lees verder

Hoe het volledige proces van ontwikkeling tot en met realisatie is verlopen kunt u lezen in deze business case. lees verder

Pekago 30 jaar

05 jun 2013 In de afgelopen dertig jaar heeft Pekago zich ontwikkeld tot een specialist in de belangrijkste vormgevingstechnologieën voor kunststof behuizingen. lees verder

Kostenbesparing met High Performance Plastics

20 mrt 2013 Dowload de whitepaper hier. Wat zijn high performance plastics? Waar worden ze voor gebruikt en wat zijn de voor- en nadelen. In ons onlangs gepubliceerde artikel wordt ingegaan op de ... lees verder

Flexibele productie

25 okt 2012 Stel, u heeft tijdelijk een tekort aan capaciteit in uw productie.

Zou het dan niet handig zijn als u gebruik kan maken van flexibele capaciteit extern? lees verder

Zou het dan niet handig zijn als u gebruik kan maken van flexibele capaciteit extern? lees verder

Innovatie 2012: TSG zonder lakken!

23 dec 2011 Het ontwerpen van grote sterke kunststof spuitgietproducten vraagt een specifieke aanpak. Dit omdat de wanddikte bij spuitgieten beperkt is (vanwege inval). Aanpassing van geometrie (ribben), versterkte grondstoffen (vulling) of ondersteuning door metalen constructies zijn hiervan voorbeelden. lees verder

Electromagnetic Compatibility (EMC)

22 dec 2011 EMC is het vermogen van elektrische apparaten / installaties om in elkaars buurt goed te kunnen blijven functioneren, zonder elkaar (ongewenst) te beïnvloeden. Bij gebrek aan EMC kunnen elektrische apparaten elkaar storen. De behuizing van elektronische apparaten is ondermeer vanwege de vormgeving steeds vaker van kunststof. Kunststoffen geven van nature geen bescherming tegen elektromagnetische straling. Als specialist in kunststof behuizingen heeft Pekago echter verschillende oplossingen beschikbaar die toch bescherming bieden. lees verder

Pekago in de spotlights

14 sep 2011 Ook in het najaar kunt u Pekago weer op aan een aantal gerenommeerde beurzen in het binnen- en buitenland aantreffen. Interesse wat wij nog op het programma hebben staan? lees verder

Slim design by smart solutions

01 aug 2011 Bij milieubewust ontwikkelen wordt vaak gebruik gemaakt van weinig, lichtgewicht en recycleerbaar materiaal. Dat heeft een gunstig effect op de kosten van het fabriceren van producten en vaak met name ook op de gebruikskosten. Zo vragen lichtgewicht toepassingen minder energie bij beweging. Minder materiaalverbruik betekent ook minder verwerking van grondstoffen, minder afval en daarmee een lagere belasting van natuur en milieu. lees verder

Vandaag besparen?

01 aug 2011 Wilt u echt direct besparen? Op actuele inkopen? Vandaag nog? Neem nu contact met ons op en daag ons uit! Loze kreten? Vage kansen? Wij zijn ervan overtuigd het tegendeel te bewijzen en partnership op waarde te schatten. lees verder

TSG: verbetering van kosten en ontwerpvrijheid; Vanderlande Industries ging u voor!

21 mrt 2011 In de vorige nieuwsbrief is aandacht besteed aan het project dat gezamenlijk met Vanderlande Industries is uitgevoerd. Hierbij zijn zwaar belaste delen van het nieuwe bagagesorteer en transport systeem uitgevoerd in kunststof met behulp van TSG technologie. Inmiddels gaat bij velen de interesse uit naar deze technologie en gaat Pekago graag in op een aantal veel gestelde vragen. lees verder

VanDerLande Industries: TSG toepassingen in het groot

01 feb 2011 Met de BAXORTER biedt VanDerLande Industries een kosteneffectieve geïntegreerde bagagehandling en –sorteeroplossing welke de efficiency voor bagageafhandeling op kleine en middelgrote luchthavens vergroot.

De dragende delen van de carriers in dit systeem, welke de bagage dragen en voortbewegen, zijn ontworpen op basis van toepassing van TSG technologie. lees verder

De dragende delen van de carriers in dit systeem, welke de bagage dragen en voortbewegen, zijn ontworpen op basis van toepassing van TSG technologie. lees verder